Zero Rooftop Penetration

Screens secure directly to the equipment

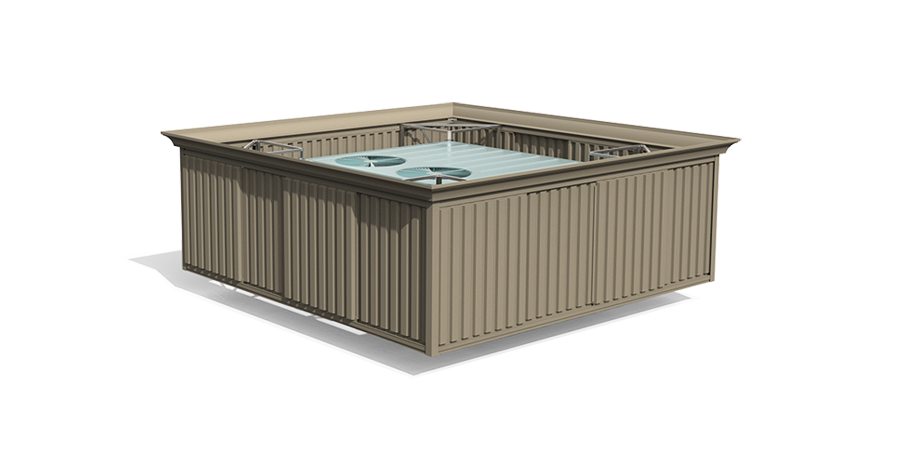

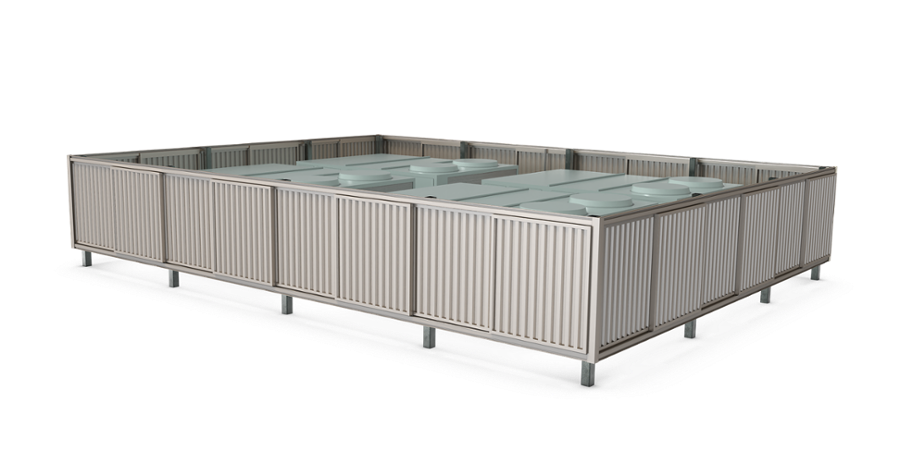

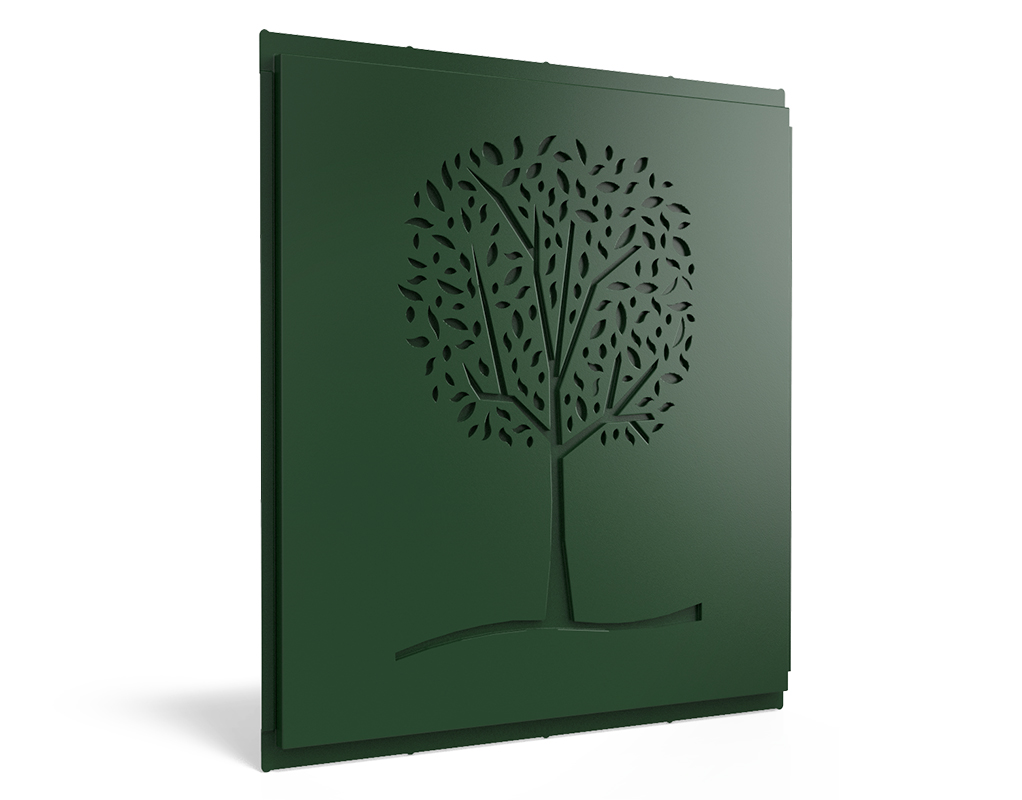

Set the bar high with durable and attractive Envisor® roof screens. Affordable and elegant, Envisor makes meeting code simple and blends into any design. Better yet: no rooftop penetration is required for installation, which gives you a clean, modern look.

Screens secure directly to the equipment

Ultimate wind speed resistance up to 115mph

Design • Manufacturing • Installation

Envisor® screens feature our patented attachment method, so they can secure directly to the equipment—no rooftop penetration required. Post-mounted options are also available.

This is the perfect alternative to parapet walls and will satisfy even the strictest of screening code requirements. Screens can be stacked up to three panels high, which means you can shield just about anything.

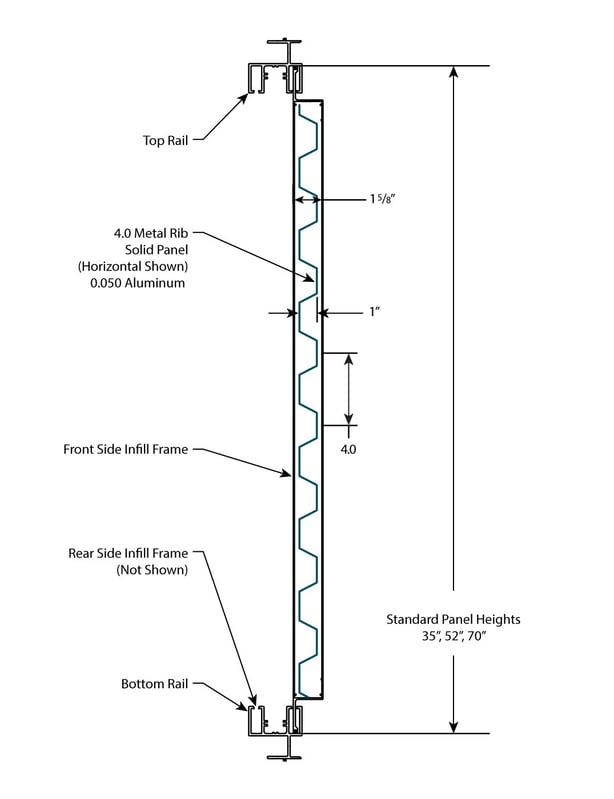

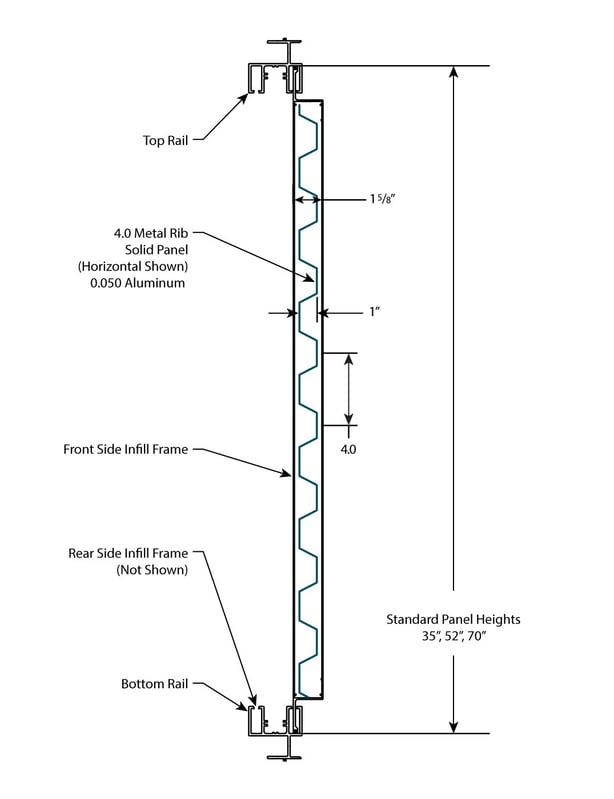

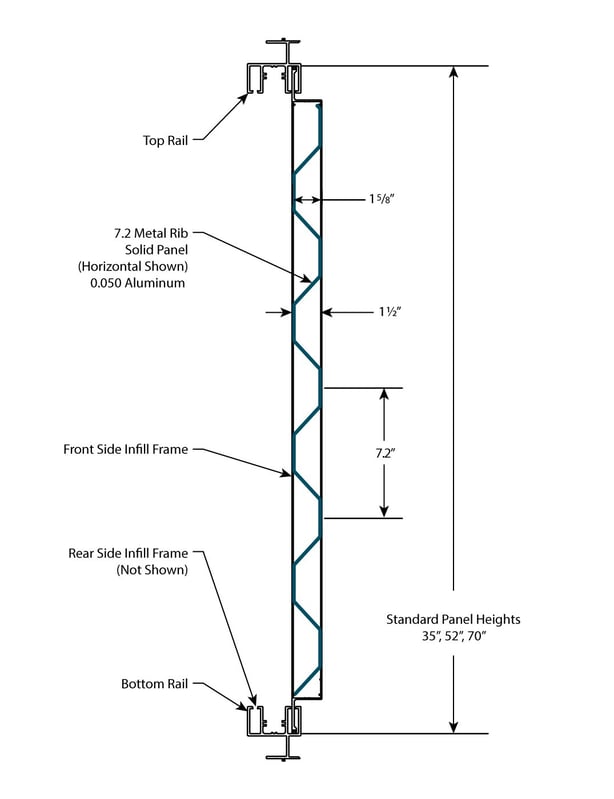

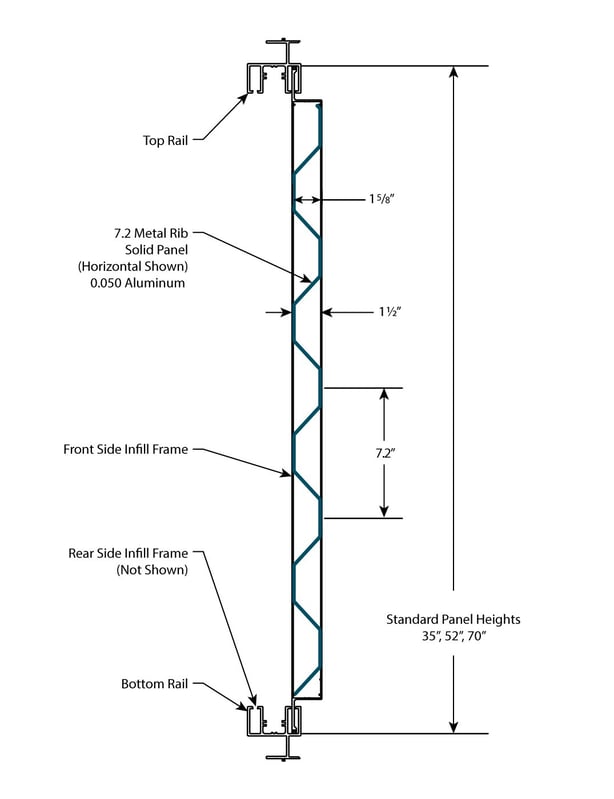

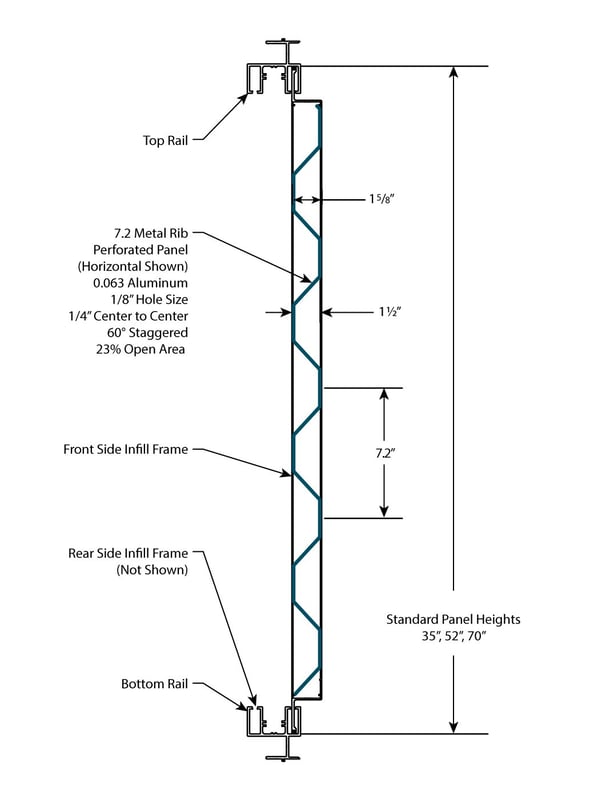

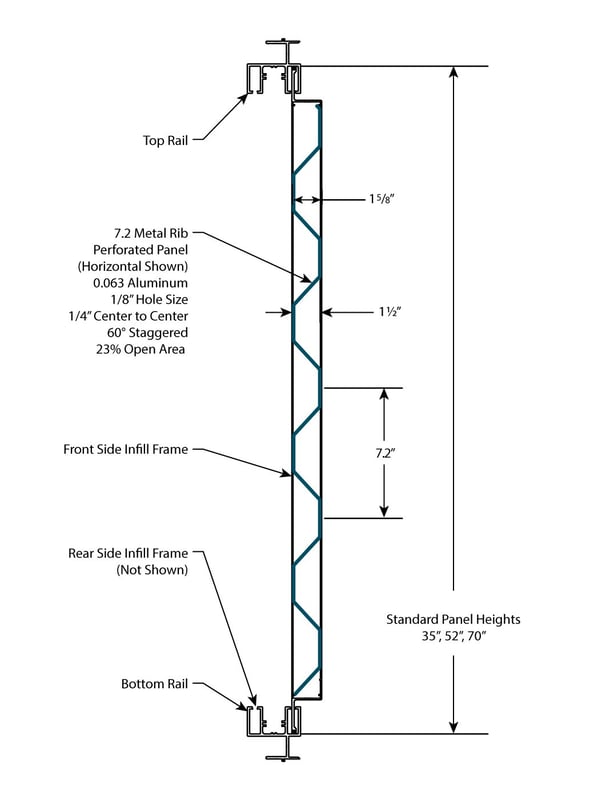

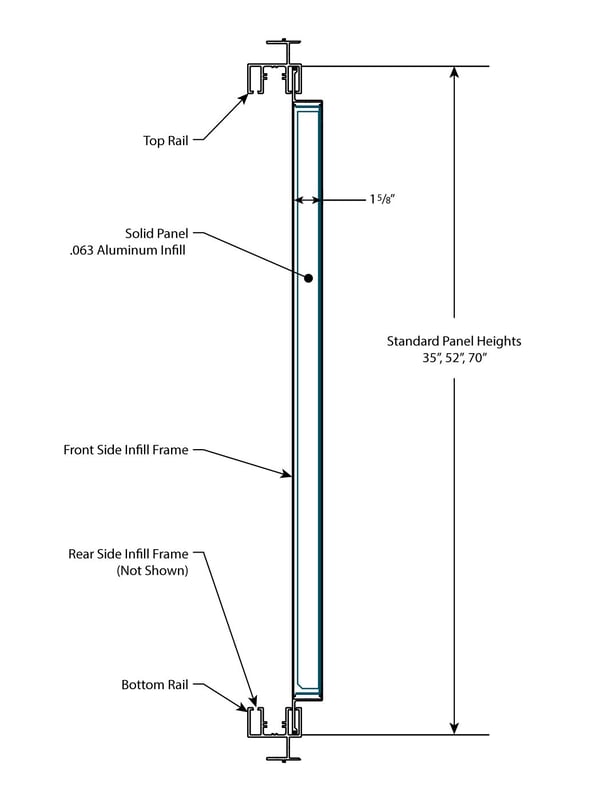

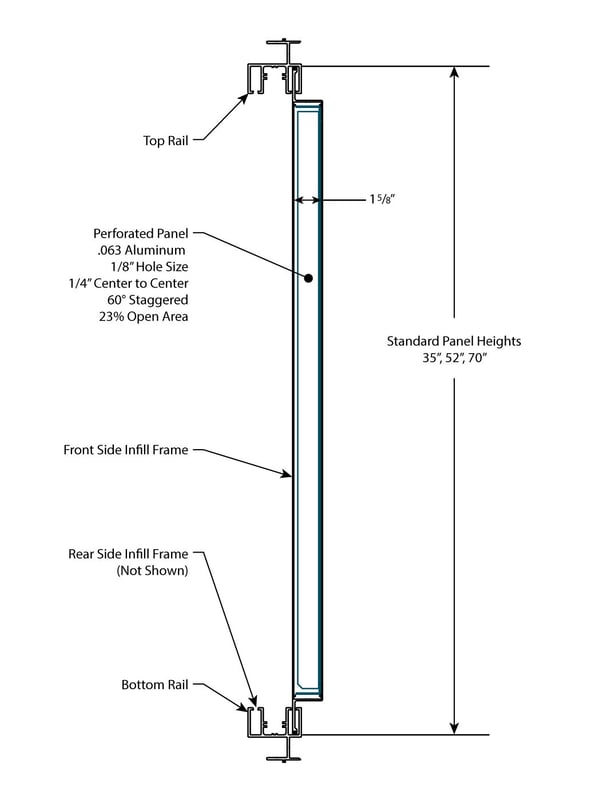

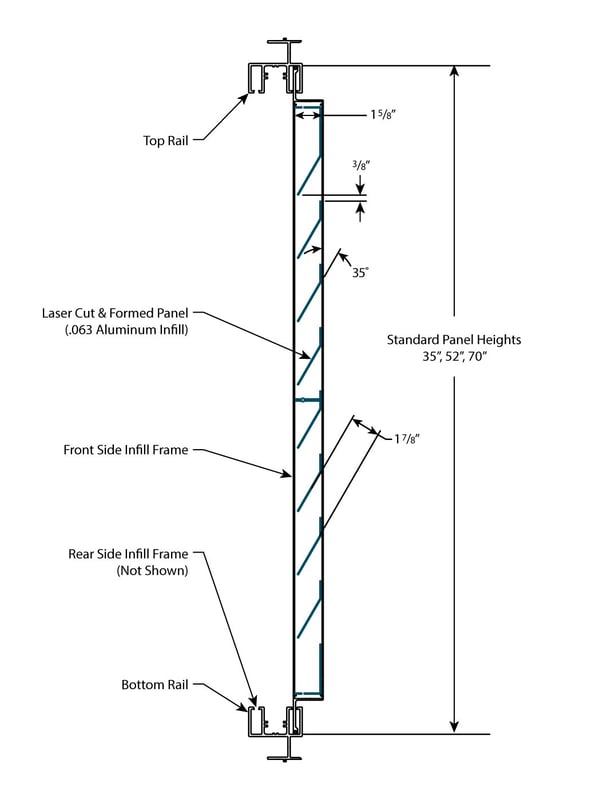

Available in a variety of all-aluminum panels with unmatched ultimate wind speed of 115mph. Our proprietary design captures the panels in the frame, meeting or exceeding code requirements in areas with high wind requirements. Choose from a wide range of custom finishing options including digital printing and our proprietary 6-stage powder coated process that will fit your project.

Our products have an ultimate wind speed ranging between 115mph - 180mph, surpassing municipal code compliance regulations.

Added reinforcements are utilized to achieve Miami Dade County requirements.

PE Stamped drawings are available on all North American projects.

Our products are resistant to mold and mildew growth.

Industry-standard testing method ASTM D5590/ASTM G21 measured a zero fungal growth value.

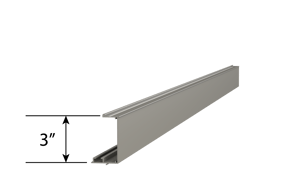

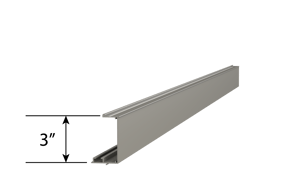

All of our Top trims use .063” wall – 6063 T5 aluminum shapes, finished

with a 4000 series powder coat process for years of never rust performance.

Metal Panels are most often ordered in one of the colors below. Want something unique?

Provide a sample, RAL or PMS number and we will color match to your specifications.

Swatches viewed on a computer screen or on printed material are intended to be a guide to our product color choices. For best results, contact us to request material samples that will provide true color representation.

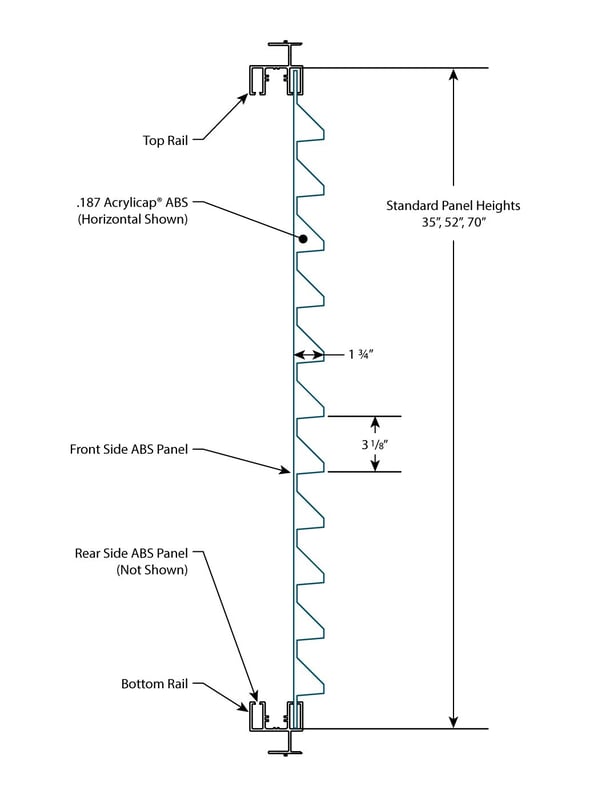

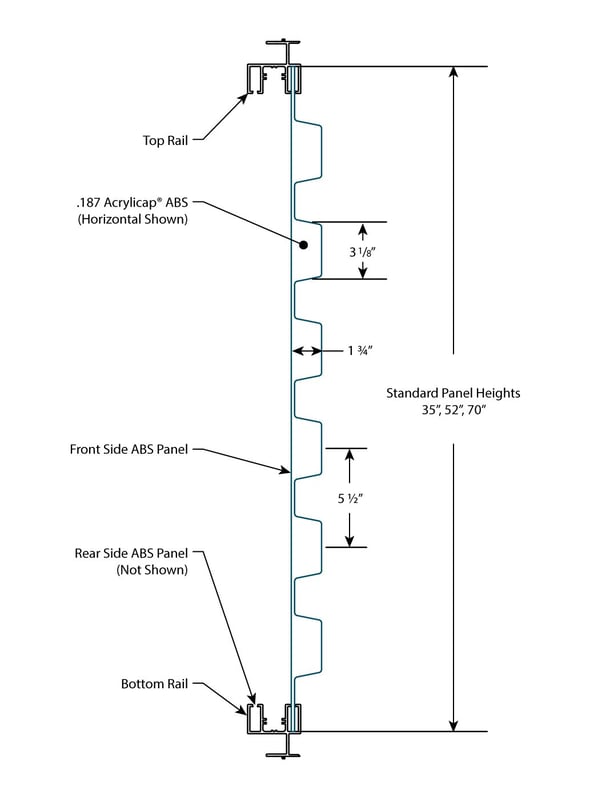

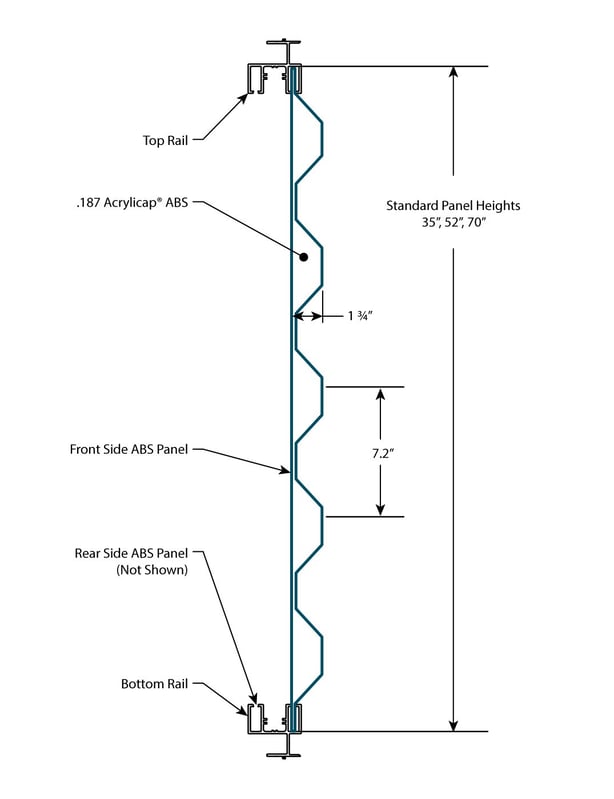

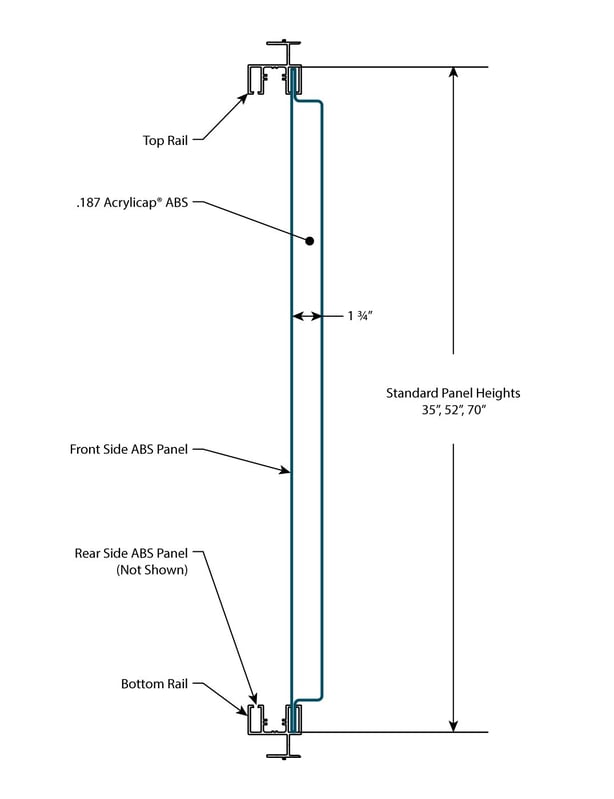

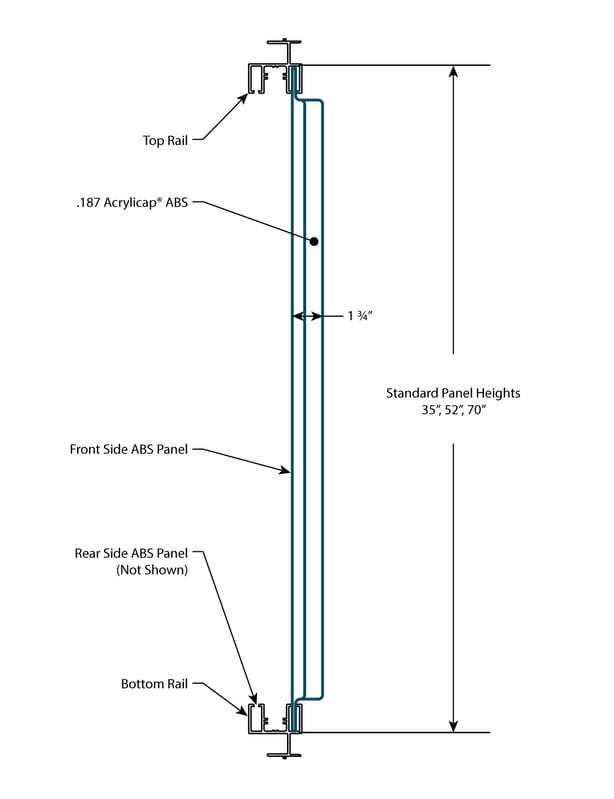

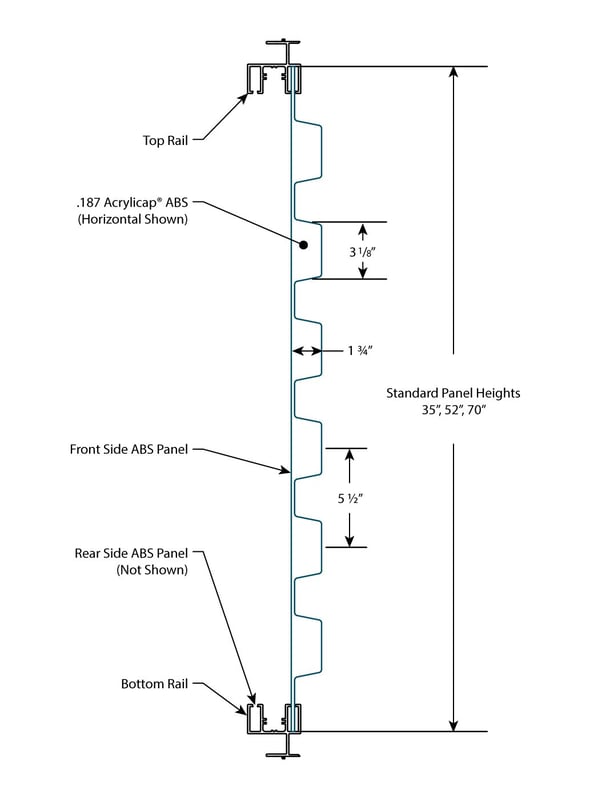

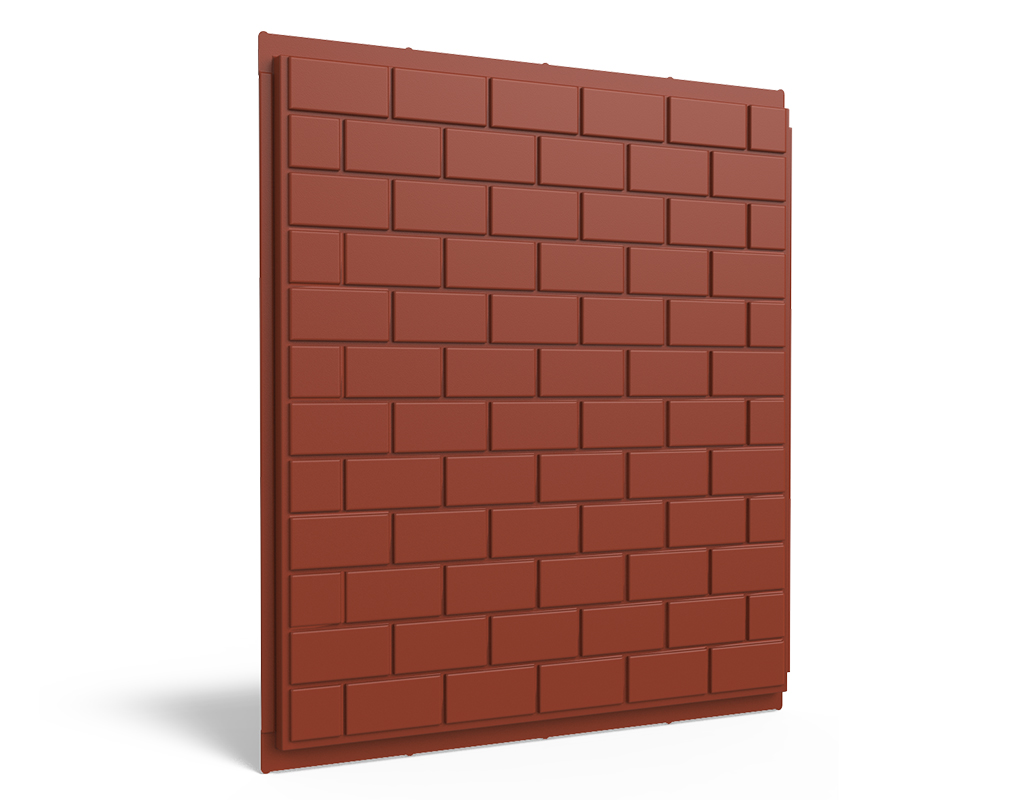

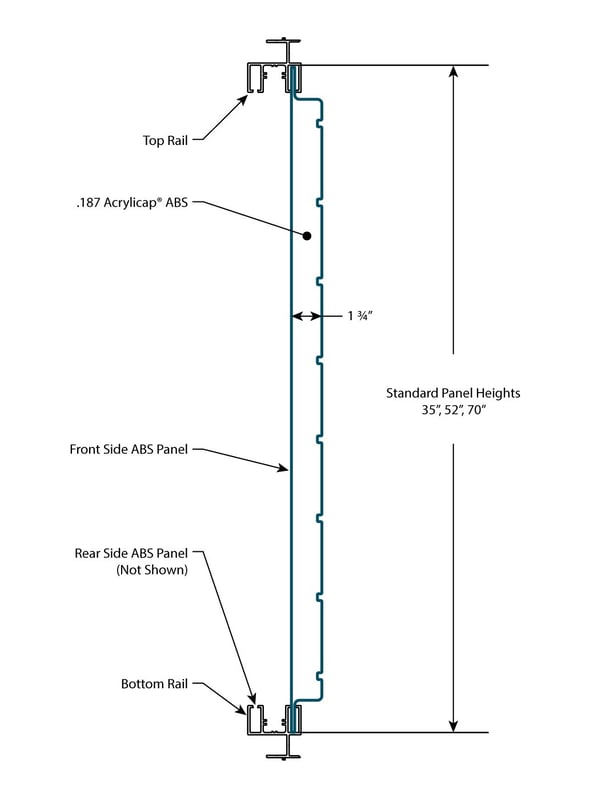

Acrylicap® ABS is a proprietary material developed by CityScapes. We start with a matching color ABS core, then laminate an acrylic outer layer to both sides of the sheet to provide a strong barrier against UV degradation. The result: superior color retention.

Acrylicap® uses .187 acrylic-capped ABS for UV protection

All panels are 45” wide

Standard panel heights are 35”, 52”, 70”

Panels can be stacked for additional coverage

Weight approximately 1.1lbs/sq ft

Our products have an ultimate wind speed ranging between 115mph - 180mph, surpassing municipal code compliance regulations.

Added reinforcements are utilized to achieve Miami Dade County requirements.

PE Stamped drawings are available on all North American projects.

Our products are resistant to mold and mildew growth.

Industry-standard testing method ASTM D5590/ASTM G21 measured a zero fungal growth value.

All of our Top trims use .063” wall – 6063 T5 aluminum shapes, finished

with a 4000 series powder coat process for years of never rust performance.

Acrylicap® ABS Panels are most often ordered in one of the colors below. Want something unique?

Provide a sample, RAL or PMS number and we will color match to your specifications.

Swatches viewed on a computer screen or on printed material are intended to be a guide to our product color choices. For best results, contact us to request material samples that will provide true color representation.

Connecting with one of our project managers is easy. Reach out today to get started.

Our project managers and product experts are here to help every step of the way, from design to installation.